Description

Mighty Line Tape’s Clear Floor Labels

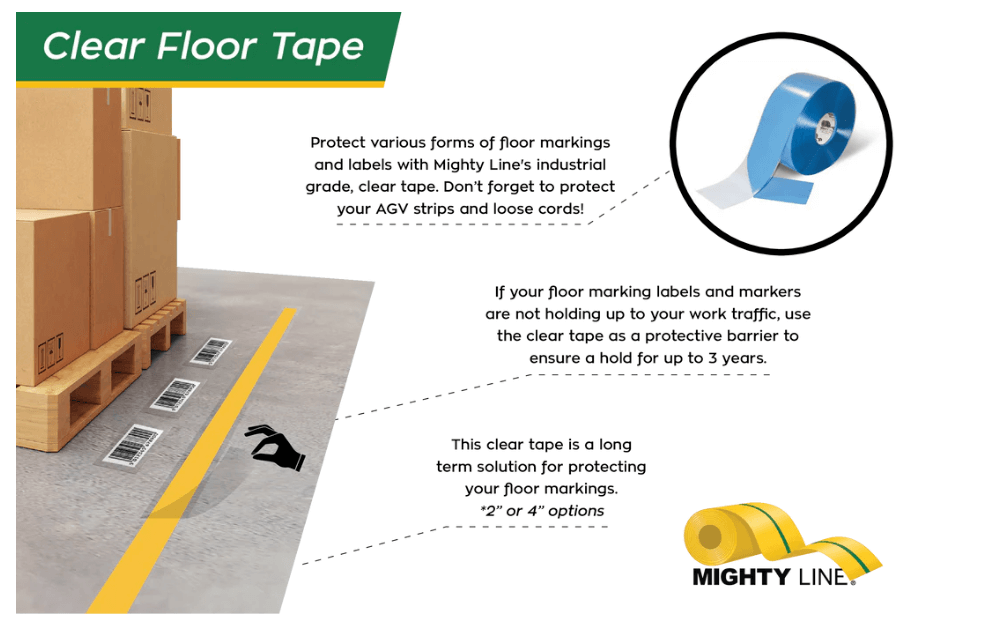

Mighty Line Tape carries clear floor labels designed for durability to protect essential facility messages. Regardless of your facility and the traffic it faces, our clear label protection tape can contain labels that showcase directions, instructions, and more.

Shop Our Collection of Label Protection Tape

Heavy-duty label protection tape is meant for flat surfaces and for areas of constant traffic. We carry the following variations of floor label protection tape:

- 6 x 10 standard pack of 100 – Flexible label protector

- 10 x 13 standard pack of 100 – Jumbo-size flexible label protector

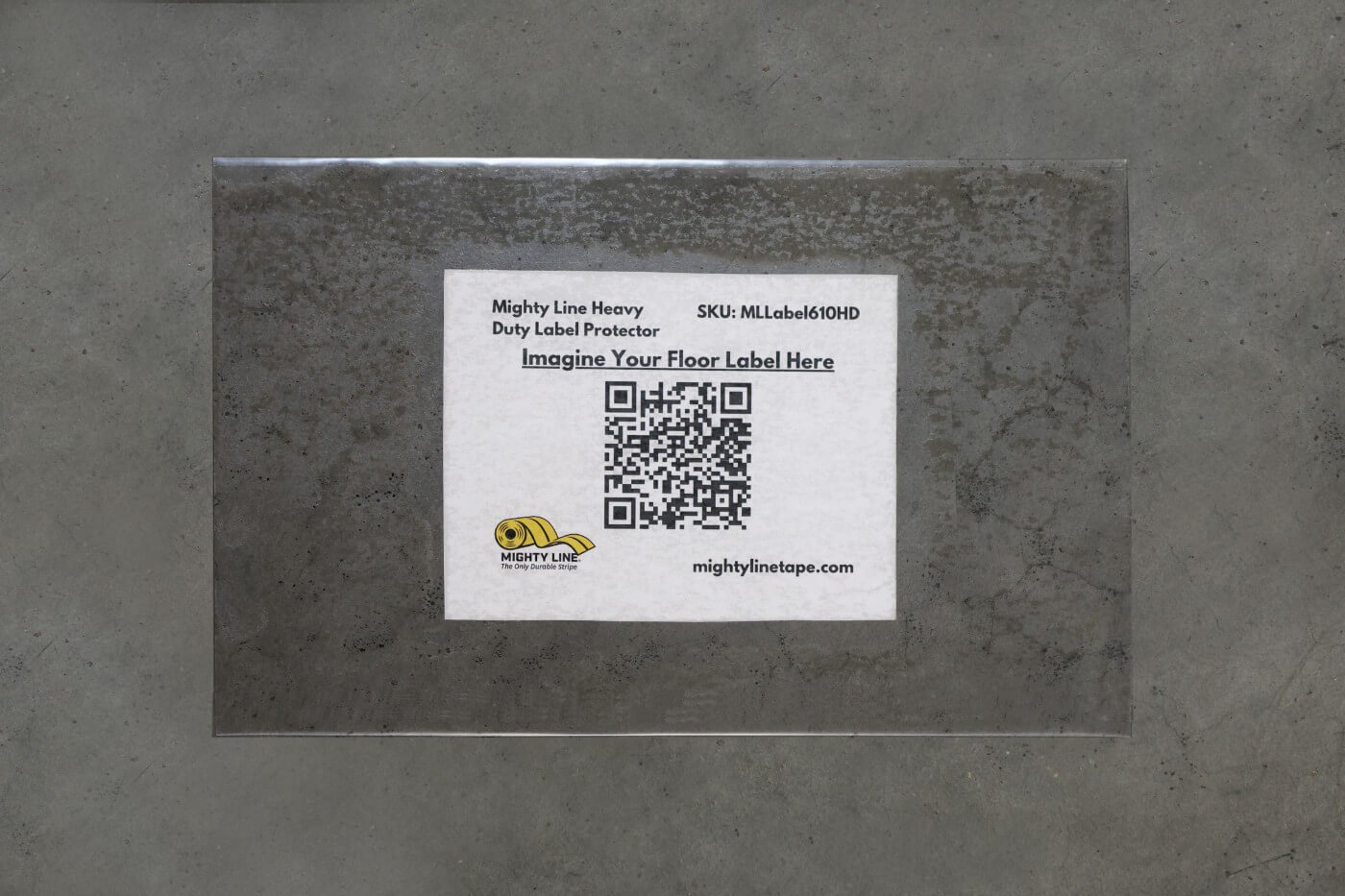

- 6 x 10 heavy-duty pack of 50 – Two times as thick as the standard version

- 10 x 13 heavy-duty pack of 50 – Jumbo-size, which is two times as thick as the standard version

Capabilities of Our Floor Labels

Our clear floor labels have the power to stay put in your facility and benefit you for years to come. Additionally, they carry the following qualities that make them ideal for warehouses, factories, and more:

- Durability – Mighty Line floor labels are 50 MIL thick for industrial use. Your improved labels will be able to handle wheel traffic and floor scrubbers with ease.

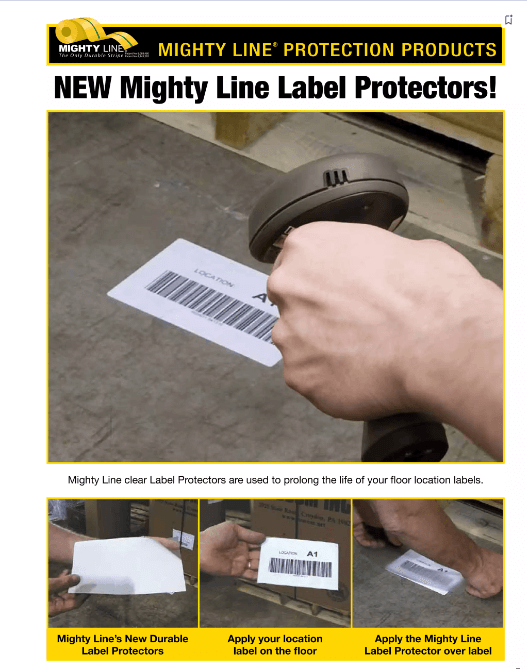

- Adaptability – These floor labels work by covering your custom labels in the warehouse. With these label protectors, you can print your own labels that direct traffic and easily highlight them. Just print a paper label and cover it with the Mighty Line clear heavy duty label protector.

- Convenience – Our label protection tape leaves minimal residue upon removal. Additionally, you can scan barcodes and QR codes through Mighty Line floor labels, keeping your workflow moving.

- Efficiency – Mighty Line clear label protectors save you money and time because our heavy-duty clear protectors are built to last!

WHY USE CLEAR LABEL PROTECTORS?

In today’s fast-paced industrial environments Mighty Line offers a wide variety of clear label protectors. Clear label protectors, especially those from the Clear range, emerge as an indispensable tool, particularly when it comes to safeguarding vital barcode and floor label information. These protectors, including the highly effective label protector tape, are designed to withstand the rigors of heavy-duty industrial wheel traffic, where the constant movement of pallets wheels, forklifts wheels, and foot traffic poses a significant risk to the integrity of labels. Let’s delve into the reasons why using Mighty Line clear label protectors is not just beneficial but essential.

Durability and Protection:

- Heavy-duty industrial tapes ensure that barcodes and floor labels remain intact and legible, even in high-traffic areas, safeguarding the vital information they carry.

- UV-resistant options protect against ink fading from direct sunlight exposure, crucial for labels placed in sunlit areas, ensuring barcode labels remain clear and scannable.

- The design of Mighty Line clear protectors enhances the protector’s hold, minimizing the risk of peeling and damage over time, ensuring the longevity of your labels.

Versatility and Customization:

- Available in pre-cut options and rolls of various widths, these protectors allow for tailored application to different label sizes, accommodating a wide range of barcode labels.

- Adhesive strengths vary to adhere to multiple surface types, from porous materials like cloth to smooth, flat surfaces, ensuring a secure hold for barcode labels across different environments.

Cost-Effectiveness and Efficiency:

- Clear label protectors are not only available in various sizes and quantities but are also designed for easy application and removal when necessary, making them a versatile solution for protecting barcode labels.

- The use of durable materials like transparent vinyl and exclusive clear adhesives extends the lifespan of labels, reducing the need for frequent replacements and ensuring the clarity and durability of barcode labels.

- Enhancing scanning accuracy and maintaining data integrity, these protectors contribute to smoother operational workflows, ultimately leading to cost savings and improved efficiency for businesses relying on barcode labels.

Incorporating clear label protectors into your organizational or industrial setting not only preserves the physical state of your labels but also ensures the continuous accuracy and efficiency of data collection and tracking processes. Whether in healthcare, retail, or manufacturing, the clarity and longevity of barcode labels facilitated by these protectors are crucial for maintaining seamless operations and compliance with regulatory standards. If your company is instrumenting kaizen, 5s Lean, Lean manufacturing, ANSI principles these clear label protectors are a very useful tool.

TYPES OF CLEAR LABEL PROTECTORS

Clear label protectors, essential for maintaining the integrity and readability of labels, including barcode labels, in various environments, come in a myriad of types, each designed to meet specific needs and applications. Understanding the diversity and functionality of these protectors can significantly enhance the effectiveness of your labeling strategy. Here’s a closer look at the types available:

Material Varieties:

- Vinyl – Offer flexibility and are suitable for curved surfaces. Vinyl protectors are particularly good for waterproofing.

- Clear Adhesive: Provides a strong bond to surfaces, ensuring the label protector stays in place.

- Mighty Line heavy duty clear label protectors are 50 mils thick and some of the most durable label protectors in the industry.

Special Features:

- UV Resistance Some protectors come with UV resistance to prevent ink from fading, crucial for labels exposed to sunlight.

- Adhesive Strength Varying adhesive strengths cater to different surface types, from smooth, flat surfaces to more porous ones like cloth, making them ideal for securing bar code labels.

- Special Types:

- Band-Aid Style: For temporary label protection, easy to apply and remove.

- Clear-View Heavy-Duty Non-Glare: Designed for secure spine label protection, minimizing glare for better barcode scanning.

Size and Application Method:

- Standard and Custom Sizes Available in pre-cut options like 1″x3″, 2″x3″, and on rolls for custom sizing, ensuring a snug fit for any label, including small bar code labels.

- Self-Adhesive & Reusable Most protectors use a peel-and-stick method for easy application, while some are designed to be reusable, allowing for multiple applications without loss of adhesion.

Incorporating the right type of clear label protector not only preserves the physical appearance and legibility of labels, including bar code labels, but also plays a pivotal role in maintaining the accuracy and efficiency of data collection and tracking processes across diverse industries such as healthcare, manufacturing, and logistics. By selecting protectors based on material, special features, and size, organizations can ensure optimal protection and longevity of their labels, contributing to smoother operational workflows and enhanced organizational efficiency.

BENEFITS OF HEAVY DUTY LABEL PROTECTORS WITH BAR CODES

Heavy-duty label protectors with barcodes are not just a functional necessity; they’re an investment in the longevity and efficiency of your business operations. Their benefits span various aspects, from durability to cost savings, making them an indispensable tool in any industry. Here’s a closer look at the multifaceted advantages they offer:

Durability and Environmental Resistance:

- Water and Chemical Resistance Withstands exposure to water and hazardous chemicals, ensuring labels, including those with bar code labels, remain protected in harsh environments.

- UV and Abrasion Resistance: Offers protection against UV rays and physical abrasion, maintaining label legibility and integrity.

- Dust, Dirt, and Oil Guard Acts as a barrier against dust, dirt, oils, and other contaminants that could obscure or damage labels, including bar code labels.

- Temperature Tolerance: Resilient in extreme temperatures, suitable for equipment used in varying environmental conditions.

Economic and Operational Benefits:

- Longevity These protectors extend the life of bar code labels, reducing the need for frequent replacements and updates, ensuring your bar code labels remain in top condition.

- Ease of Installation and Removal: Designed for hassle-free application and removal, without leaving residue or damaging surfaces.

- Cost Savings By protecting the initial investment in high-quality bar code labels, businesses can avoid the expenses associated with frequent reprinting and reapplication, making barcode labels more cost-effective in the long run.

- Compliance and Accuracy Helps maintain compliance in regulated industries by ensuring barcode labels remain readable and scannable, thus reducing errors and improving supply chain management, ensuring your barcode labels meet industry standards.

- Versatility and Customization:

- Adaptability Compatible with various types of barcode labels, including both linear and 2D barcodes, offering flexibility across applications and making your bar code labels versatile.

- Customization Available in custom shapes, sizes, and materials to meet specific business needs and ensure optimal performance in different settings, our custom barcode labels are designed to suit your unique requirements.

- Industry-Wide Use Suitable for a broad range of industries, including retail, warehousing, healthcare, and manufacturing, among others, our barcode labels are versatile and adaptable.

By integrating heavy-duty bar code label protectors into your operational toolkit, you not only safeguard your labels against physical and environmental threats but also streamline your inventory and asset tracking processes with durable barcode labels and asset tags. This, in turn, boosts overall efficiency and contributes to a leaner, more effective warehousing or manufacturing environment.

APPLICATION AREAS FOR CLEAR LABEL PROTECTORS

Clear label protectors serve as a versatile tool across a wide range of industries and applications, ensuring that essential information on your printed labels remains visible and intact, irrespective of the environmental conditions or handling it might undergo.

Product and Inventory Management:

- Product Labels: Safeguards details such as product specifications, ingredients, and safety instructions.

- Inventory Labels Essential for warehouses and retail environments to maintain accurate tracking and organization of stock, our inventory barcodes and QR code labels ensure seamless operations.

Professional and Educational Settings:

- Name Tags and School Supplies Protects clarity of names and titles for better identification in professional settings; ensures labels on school supplies remain legible, making your printed labels an essential tool for organization and identification.

- Educational Materials: Textbooks and notebooks are kept intact, preserving critical information for educational purposes.

Healthcare and Laboratory Use:

- Patient Information and Medication Labels In healthcare settings, clear label protectors with barcode labels safeguard patient information and medication labels, ensuring accuracy and safety.

- Laboratory Equipment and Samples Protects labels on various laboratory equipment, samples, or supplies with barcode labels, keeping necessary information accessible and undamaged.

In addition to these specific applications, clear label protectors find usage in broader areas, enhancing operational efficiency and compliance across sectors.

- Broad Industry Applications:

- Healthcare Clinics and pharmacies utilize protectors with QR code labels to shield labels from water in the storage area on the floor

- Warehouses and Manufacturing : Protects important barcodes, 2D barcodes, 3D barcodes, QR codes on the concrete floor.

- Retail : Use clear label protectors to protect certain printed labels on the floor.

By implementing clear label protectors with QR code labels, organizations can significantly reduce the risk of misidentification, data errors, and non-compliance, leading to a more efficient, safe, and productive environment. Whether it’s preserving the legibility of asset tags in a bustling warehouse or protecting patient information in a busy healthcare setting, the application of clear label protectors is a simple yet effective step toward enhanced operational integrity.

INSTALLATION TIPS AND BEST PRACTICES

When installing QR-enhanced clear label protectors, following a set of best practices can ensure their effectiveness and longevity. Here are some insightful tips and methodologies for an optimal installation process:

PREPARATION AND APPLICATION

- Surface Cleaning:

- Begin by thoroughly cleaning the application surface with an alcohol-based cleaner to remove any dirt, oil, or residue that could interfere with adhesion.

- This step is crucial for ensuring that the label protector adheres properly and remains in place over time.

- Application Method:

- Peel and Stick Carefully peel off the backing of the clear label protector with Mighty Line technology. Position the protector over the label, ensuring correct alignment, and then gently place it on the surface.

- Tamping for Activation Once positioned, walk on or drive over the label to firmly press down on the protector. This action activates the pressure-sensitive adhesive, ensuring a secure bond.

- Ensuring Durability:

- Opt for Mighty Line heavy duty label protectors with beveled edges and recessed adhesive. These features not only add to the durability by minimizing peeling and lifting but also simplify the application process, making them a perfect match for Mighty Line’s robust requirements.

CUSTOM DIY SOLUTIONS

- Homemade Protectors For a custom approach, consider creating a homemade label protector using a base with four holes from hardware stores like Lowes. Improve its functionality by filling the holes with epoxy for a smoother surface and adding a larger handle for easier manipulation.

- Alternative DIY Method Utilize 4 1/2 inch dent pullers from Harbor Freight as an innovative DIY label protector. This method offers a quick and cost-effective solution for protecting labels in less demanding environments.

CONSIDERATIONS FOR BARCODE LABELS AND SCANNERS

When choosing barcode labels and scanners, consider the following to ensure compatibility and performance:

- Material and Durability: Select labels that can withstand the environmental conditions they will be exposed to.

- Adhesive Strength and Label Size Match the adhesive strength and label size to the application surface and intended use, especially when dealing with barcode labels or small barcode labels to ensure maximum adhesion and compatibility.

- Scanner Compatibility Ensure the barcode labels are compatible with the types of scanners used in your operations, considering factors like connectivity, scanning distance, and angle. Incorporating scannable QR codes can further enhance versatility and efficiency.

- Design for Clarity Focus on clarity and readability in label design, considering optimal sizing, placement, and color contrast to enhance scannability, particularly for barcode labels.

Incorporating these best practices and considerations into the installation process of barcode-enhanced clear label protectors not only maximizes their protective qualities but also supports efficient and accurate scanning and tracking within various operational environments.

MAINTAINING AND REPLACING CLEAR LABEL PROTECTORS

Maintaining the integrity and readability of clear label protectors, especially those enhanced with barcodes, is crucial for ensuring the seamless operation of inventory management and tracking systems. Here are practical steps and best practices for the upkeep and eventual replacement of these protectors:

REGULAR MAINTENANCE:

Cleaning Process:

- Use a microfiber cloth to gently wipe down the label protectors. This method is effective for removing dust and minor smudges without damaging the surface, making it ideal for non-reflecting surfaces.

- For more thorough cleaning, a solution of Dawn dish soap and 91% alcohol can be used. Apply with a soft, non-abrasive pad, ensuring not to soak the label or protector.

Routine Dusting and Cleaning:

- Incorporate regular dusting and cleaning into the maintenance schedule. This prevents the accumulation of dirt and grime that can obscure barcode readability.

- Audit the condition of barcode labels and their protectors periodically, checking for signs of wear such as fading, tearing, or peeling. This ensures the labels remain in top condition.

WHEN TO REPLACE:

Audit and Replacement Criteria:

- Faded, torn, or peeling labels are clear indicators that the protector is no longer providing adequate protection for your barcodes labels.

- Smudged type or illegible digits/letters compromise the functionality of barcode labels and QR codes, necessitating immediate replacement to maintain efficiency.

- Outdated information or unreadable barcodes/QR codes on your barcode labels are a sign that essential data must be clear and current for effective tracking and management.

Replacement Process:

- Remove the old label protector carefully to avoid damaging the surface underneath. If residue is left behind, gently clean the area with an alcohol-based solution.

- Apply a new clear label protector, ensuring it’s properly aligned and firmly pressed down to avoid air bubbles and ensure maximum adhesion with dura-clear technology.

ADVANCED MAINTENANCE TIPS:

Drying Techniques:

- After a deep clean, drying the label protectors in a dust-free environment is recommended. Avoid using direct heat or sunlight as it may warp or damage the non-reflecting protector.

- An industrial sweeper can be utilized for removing excess moisture and debris, offering a significant improvement over air drying, which might leave water spots or residue.

Additional information

| Width | 4”X6” Heavy Duty Label Protector Pack of 50, 6”X10” Label Protector Pack of 100, 6”X10” Heavy Duty Label Protector Pack of 50, 10”X13” Label Protector Pack of 100, 10”X13” Heavy Duty Label Protector Pack of 50 |

|---|